- Homepage

- Products

- Our plus points

- Partnership

- Company

- Documentation

- News

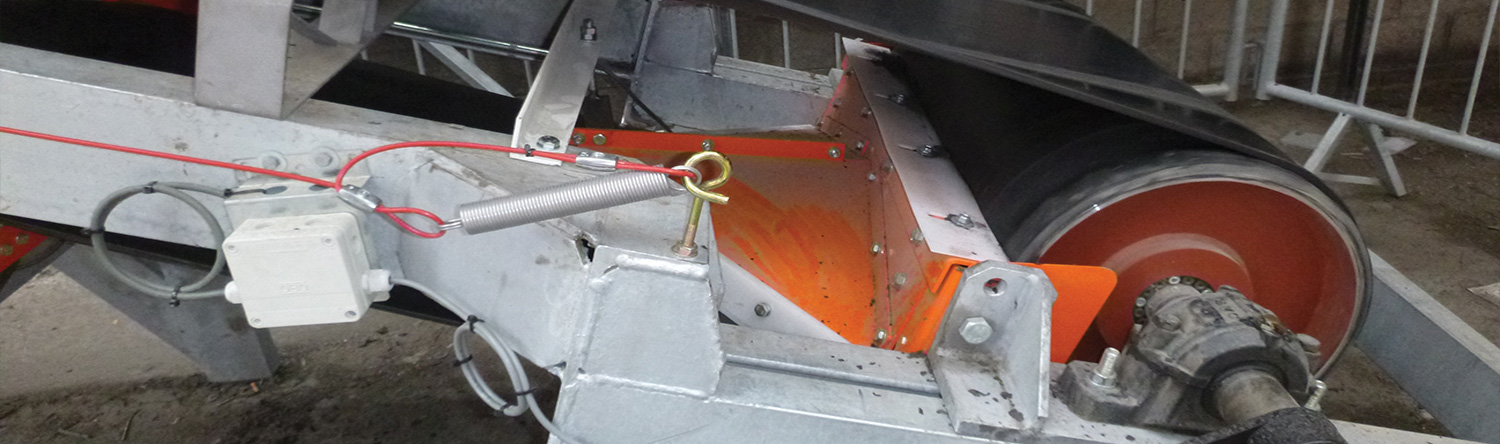

- El OPTIM’AUGE es LA solución para garantizar la estanqueidad de las cintas transportadoras

- Magazine INFOVRAC Juillet 2023 | Optim’Auge

- Press : Modern Mining -12/2022 – BRELKO Scrapers

- 12 to 14 February 2019 EXPOSOLIDOS – Barcelona

- 01. 2018 | New installation of Optim’Auge 800-4000

- A new logo for Europe

- August 2017 | Happy birthday to Brelko

- Trade Shows: France – SIM 2017 – Metz

- Video 2017: OFC | Optim’For Conveyors

- English